Weiming Environmental Protection Equipment Co.,LTD. As a subsidiary of Weiming, is a National High-tech Enterprise and one of the largest and most advanced high-tech companies in waste incineration technology development and equipment manufacture in China. It mainly produces MSW incineration boilers, flue gas cleaning facilities and other waste trentment set equipment which have been applied in the projects of Weiming. Owing to its abundant operating experience and great efforts in technology innovation these years, it has been matured in production. Continuing to maintain progressiveness of technology and equipments, its products reach entirely the international advanced level accordingly.

? Innovative And Efficient R&D Team

Weiming sets up a technology committee in charge of R&D which is directed by the Chairman of Weiming.

Weiming operates two R&D centers of MSW treatment in Shanghai and Wenzhou with seven specialized design research offices for the purpose of customized technique research and design. Weiming has more than 100 professional engineers, majoring in thermal engineering, mechanical design, boiler,automatic control, Power Engineering and environmental protection,etc., and over 40 of which have medium-grade and senior profession titles. Those technical backbone of R&D centers are experienced in execution of science and technology projects and have Participated in series of researches under National 863 Program and key Projects of Science and technology in Provisional level.

? Rich Harvest In R&D

Weiming ranks among the first enterprises to have independent patents in incineration of solid waste. There are nearly 80 patents and software copyrights. Weiming engaged in two researches “Complete-Set Technology and Equipment of Municipal Solid Waste Treatment” and “Control Technology and System Integration against Secondary Pollution from Municipal Solid Waste Incineration”under National 863 Program and one research under National Torch Plan.

Weiming participated in formulating China’s industrial standards including “Construction Standards of Municipal Solid Waste Incineration Project” and “Factory Evaluation Standards of MSW Incineration”.

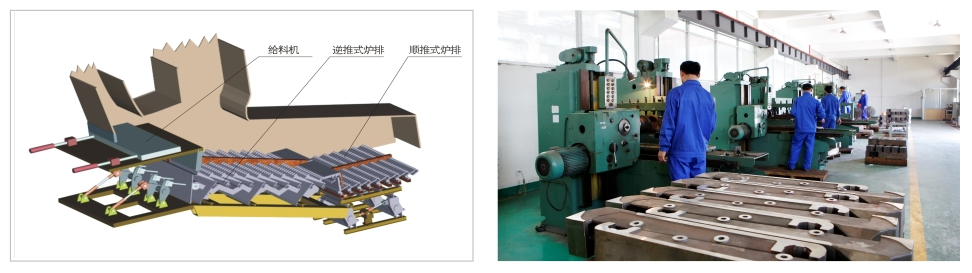

? Multicolumn Reciprocating Grate

Weiming produces series of Multicolumn Reciprocating Grates ranging from 160t/d to 750t/d to meet specific needs. Multicolumn Reciprocating Grate is composed of reverse pushing grate and forward pushing grate in which garbage is burned basically on the reverse pushing grate and then dropped to the forward pushing grate for sustained buring with the ultimate loss of ignition under 3%.

The grate is tailored to the characteristic of MSW in China of high moisture,low calorific and unsorted on which the garbage can be burned stably and completely without any accelerant.

Based on the distribution uniformity of the material layer and good levelness of fire bed, the grate can run continuously for a long time and the total operation time per year amounts to 8000 hours.

The grate is connected tightly and easy to be adjusted. Due to the distinctive modularity, the grate can be tailored to meet various requirement of different projects.

? Flue Gas Cleaning System

Weiming developed a flue gas claening system which adopted the most advanced integrated process” SNCR denitrification + dry&semi-dry method for deacidification+activated carbon absorption+dust filtration bag house”, by which flue gas treated meets the national standard for pollution control. Our on-line monitoring system through which flue gas is connected with the local environmental authorities and display screens in the entrance of every plant show the real-time data of flue gas emission to the public.

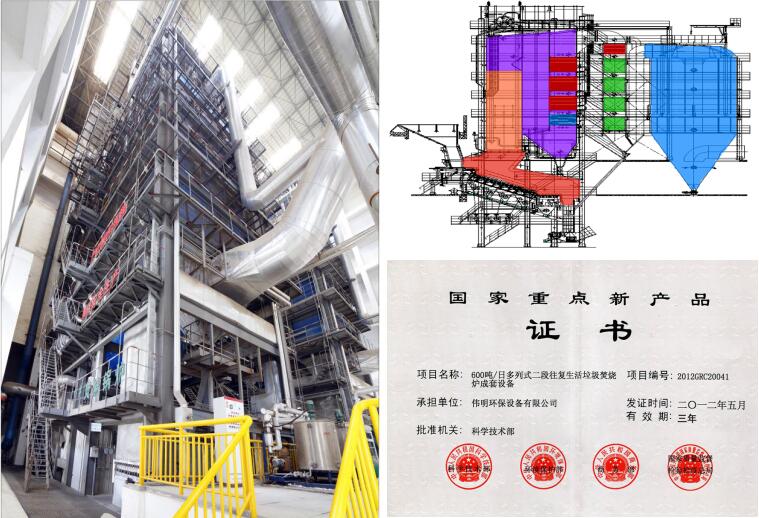

? Boiler R&D and design

We have a professional team with expertise in waste incineration boiler who used our independently developed waste incineration technology and developed the first fully domestically manufactured waste incineration boiler, bridging a technological gap in China. Through integrating a range of combustion technology at home and in the world, we use our independently owned core technologies in developing a large variety and multiple type of waste incineration boiler in accordance with the incineration performance required by different type of waste, the different features of fuel used for burning waste in different cities, climate conditions, and regional characteristics. Among them all, our vertical, horizontal, and π-shaped innovative boilers are able to meet with the demands of different projects. Currently our boiler R&D has obtained 7 patents for invention and dozens of patents for utility models, ranking top in the industry.

During the development, we have continuously practiced innovation and optimized boiler design to ensure that the waste is fully burnt and high heat exchange efficiency has been achieved; by applying smoke temperature and speed control and appropriate heating surface structure design, we aim to prevent high and low-temperature corrosion caused by the corrosive content in the smoke and gas, and therefore effectively increase the continuous operation of the boiler and service life of the equipment. In addition, we closely follow up on the operation of each waste incineration and power generation projects, constantly improve boiler design, and timely upgrade the technology according to the changes of properties in the waste and environment protection requirements in order to ensure power generation efficiency and maintain our leading position in incineration technology in China.

To answer the solid waste disposalnew trend and meet with the market needs, on the basis of domestic waste incineration boiler, we further developed other types of waste incineration boilers that contain the mixture of biogas, dried sludge, crop straw and general industrial solid waste. We also developed boilers for fuel derived from waste, waste plastic, carbon black tail gas, and landscaping waste.

? Development of automation control system

We have established automation control research center that is responsible for the software development for the automation control system of municipal domestic waste incineration and power generation industry, system design, electric control equipment, programming and debugging, engineering and installation, as well as technical services. We are dedicated to independent research and development and innovation; we have established cooperation with world renowned automation companies including ABB and GE. Our independently developed automation control products boast of high reliability, openness.

Currently our automation control production line has covered all aspects of automation control in waste incineration power plant, including the factory-wide DCS control system, ACCS grate control system, flue gas treatment system, water treatment system, and supervisory information system. All of above systems are able to be seamlessly incorporated in the factory-wide DCS control system to achieve distributed control, centralized operation, and hierarchical administration in the entire waste incineration power plant.